The Brooklyn Daily Eagle from Brooklyn, New York • Page 53

- Publication:

- The Brooklyn Daily Eaglei

- Location:

- Brooklyn, New York

- Issue Date:

- Page:

- 53

Extracted Article Text (OCR)

THE BROOKLYN DAILY EAGLE. NEW SATURDAY. MAY 20. 1911. YORK.

SATURDAY. MAY 20. 1911. .9 jlL 1" 1 linn iiiiiii, iwiwimiiiwwjit.iii i i iiii tu 1 1. mini ul 14 iai I wmn timm i.inrii wirm tm JaaA I'linn nimimimiT bhhiii i mm ma inwiii ytfiLiq r- mm mm nam i mdhhh jj 1 I meicm nuvxco conpmri --Wjr-'.

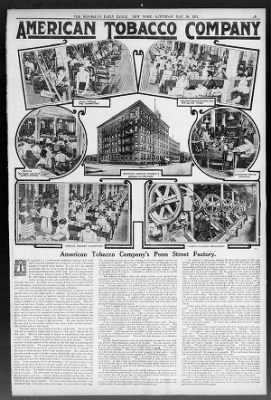

cirr, tmm, I If If i PI III (oWF70 DJPI PAWING TOffCCO CUTTNG CWMr gT American Tobacco Company's Penn Street Factory. Mill HE organization of a manufacturing establishment employing 1 ,600 people and its successful management year in and year out is one of the greatest triumphs of twentieth century progress. It is also one of the industrial achievements which has served to make Brooklyn famous as one of the greatest manufacturing centers of the world. Such is the cigarette factory of the American Tobacco Company at Wythe avenue and Pcnn street. Its 1 ,600 employes would make a humming, prosperous village.

Com The machines for making paper cigarettes like those which produce the' little cigars are large, and to the novice who looks at them for the first time they seem very complicated. But they work with perfect smoothness. The tobacco, which has previously been shredded and blended, is brought in contact with the little strip of white paper, which is deftly rolled around it and the finished cigarette is shot through a tube to be picked up and put into a tray by a girl in waiting. But those cigarettes which require to be tipped with cork have to go through a separate process. This is a very ingenious and rapid process.

The cork, which is very thin, comes in sheets about the size of my lady's note paper. This is divided in strips the size required for the mouthpiece of the cigarette. These strips are placed on a machine, of which there are about I 50 at the factory, and the cigarettes are passed down to them automatically and the cork tip is attached. The work is so quickly and efficiently done that the observer has to watch the process carefully before he can tell just how the work is accomplished. The same peculiarity prevails here that attaches to the other departments of the factory: There is little or no handwork.

The machines do it all. An operative sits at each machine and carefully watches each little cigarette as it passes along. She adjusts one now and then, when it has been shoved a little out of place, or picks out one that is defective. But aside from this the product is touched by human hands but very little, indeed. These machines are so constructed lhit there is no possibility of oil coming in contact with the cigarettes as they are passing through.

Another feature of this factory is the machine shop, which employs 20 men continuously. To this shop is brought any machinery which gets out of oVder from its constant use. Not only is repairing done here, bnt entire pants are supplied, and the workers are so expert that they manage to keep the apparatus going all the time, in spite of the fact that iron and steel will break when subjected to constant use. A part of this department is the grinding of the knives used on the machines used in shredding the tobacco used in the fillers of the cigarettes. This grindstone is six feet in diameter and the knives have to hi ground for six or seven minutes.

The knives, after making from four to five hundred cuts, have to be sharpened. The making of the paper cigarettes forms the bulk of the business done at this manufactory. The packing room of the factory is a busy place. Operatives work by the piece. It is evident at a glance that they do not intend to lose any time.

There is no conversation. The cigarettes are gently guided into the pasteboard boxes, which are quickly closed. These small boxes are put into what are called cartons, which are covered with wax paper, and they are ready for market. One carton holds 500 cigarettes. The room where- the packers are at work is well lighted, and there is a hum and drive prevailing here which is inspiring.

The operatives look well. They evidently enjoy their work. The rules don't seem to bear heavily upon them. A half hour at noon and a half holiday on Saturday seem to have had a good effect upon them. The procuring of help under these circumstances is not difficult.

Not only this but the kind of workers that are most desired by the company are procurable. Peace and harmony between employers and employed is another natural result of the system. As further evidence of the determination of the American Tobacco Company thai their Penn street factory shall be perfectly clean, it may be said that they employ twelve to fifteen women to sweep and to scrub the floors continuously. By this means the factor)' from basement to the top floor always looks as neat and tidy as a New England kitchen. There is a marked departure from the old practice, which still prevails in some quarters, which allows rubbish to accumulate in a factory, and to consider that dirt is a necessary evil in the business of manufacturing tobacco.

The operatives in this establishment are very neatly and becomingly clad. They were evidently taught to take pride in their appearance, and to make just as good a record for themselves as they possibly could. After a visit to this great manufactory and an inspection of all the processes in th! production of cigarettes the marvelous increase in this form of smoking can be understood. Pure paper, with every possible care and attention in the making of cigarettes, have been made extremely attractive to the smoker. Mod with brushes are busy all the time sweeping- the floor and promptly removing any accumulations" of material.

Operatives are not allowed to have any belongings near the machines, not even lunch boxes or packages. In a quiet corner of this big room is the hospital, where a girl suddenly taken ill can receive treatment and often avoids the loss of a day's wages by having to go to her home for some trifling ill, easily remedied. There is a medicine closet in the hospital, a comfortable cot and hot and cold water is available for use whenever it is required. The production of domestic tobacco has recently received a great impetus by improvements which have Been introduced in growing the Connecticut leaf under cheesecloth. The method is not new, but as the result of experiments- by the Agricultural Department of the United States government better results have been gained than has ever been known before.

So much improved has the outlook become for growing this tobacco, that a wonderful demand has sprung up for farms in Connecticut and Massachusetts, and the price of these lands has greatly increased. Connecticut tobacco has no equal in certain departments of cigar manufacture, and the prospect of an increased supply of this wonderful product is good news for smokers, and is a source of encouragement to all those interested in this line of business. So tangible are the results that have come to the experimenters in tobacco culture that a number of new companies have recently been formed with large capital to take ud these heretofore unoccupied lands and devote them to the growing of Connecticut seed leaf tobacco. A nurse is supplied by the company who is always on hand to treat these emergency cases, as they may arise. At the half hour at noon tea and coffee are heated for the girls and provision is made for lunching with comfort.

It has been found that the girls work better in a bright roomy factory like this. They are far more regular in their service. Experts in this department make from $10 to $12 a week, and are very seldom absent from their tasks. The total output of the little cigars for a month, which is considered as a standard of its kind, is from twenty to twenty-five millions. A very interesting feature of this department of 300 girls is the fire drill.

The gong sounds and every girl instantly stops what she may be doing and rises to her feet. The company then passts in regular order down the wide aisles to the main exits. No girl tries to get ahead of another. They follow along in as perfect order as is maintained in a public school. At the main exits men are stationed to assist in maintaining perfect order and to prevent crowding should any be attempted.

By this system this large room can be entirely emptied in forty seconds. There are three main stairways and an abundance of fire escapes. On other floors of the factory where the paper cigarettes are made the same conditions prevail as those described as existing on the top floor. The same ingenuity in the invention of machinery has made these other departments of manufactory great producers. It is not many years ago that cigarettes were made entirely by hand.

Now they are made entirely by machinery. One of these machines produces 200,000 cigarettes a day, and while some others do not have nearly as large a capacity the total made in a month at this factory alone reaches the enormous aggregate of 1 50,000,000 cigarettes. To do this a large number of machines are required. So accurate are they in their work that neaily every cigarette is a perfect one. The girls have orders to throw out every one that is not perfect.

In order to make sure that no blemishes escape, the product receives three different inspections, that is, every single cigarette of the many millions which are made at this factory is carefully examined by three different persons, all intent upon finding imperfections if any there are. For the purpose of extracting nails or other metallic substances which may have gotten into the tobacco and escaped detection, it is run over a belt supplied with an electro magnet, which extracts them and prevents injury to other machinery through which the tobacco passes in its progress to the stage of a perfect cigarette. The mixing of the various kinds of tobacco which form the filler is arranged in such a way as to maintain their high standard and secure a uniform result, thus securing to the fastidious smoker the same quality of his cigarette from year to year. munities no larger than this make considerable noise in the world and are frequently heard from. To conduct such an industrial beehive with its army of workers and avoid disputes, confusions and annoyances is worthy of being chronicled among tli3 great things done in Brooklyn, along with the things made in Brooklyn.

One of the most remarkable developments in the manufacture of cigarettes is the fact that the work is now done almost entirely by machinery. So accurate is this machinery, that vast quantities of the product ars turned out every day with such a small percentage of losses by errors that they are npt worth noting. This situation has called for a large number of skilled workers, who are intelligent, industrious and order loving. These have been found right here in Brooklyn, and the proprietors of this manufactory have set themselves to making the conditions under which their employes labor just as agreeable as possible. Absolutely clean floors, no paper or refuse about the machines, a hospital for emergency cases or temporary ills, commodious dressing rooms with broad shelves for big hats, plenty of light from numerous windows, a fire drill which is a splendid protection from fire.

These are a few of the advantages for employes which, have been introduced by the American Tobacco Company at their big factory. The result has been that they have never had any labor troubles, and their workers have a bright, interested appearance. They do their work as if they loved it. This model tobacco factory consists of six floors and basement. On the top floor 300 girls are engaged in making what are known as "little cigars," Between the Acts little cigars.

They are made entirely of tobacco, in contradistinction from cigarettes wrapped in paper. These three hundred operatives make an extremely interesting group as they sit at their machines and handle the tobacco in its several processes. The filler' material is carefully, prepared and the quantity for each little cigar is accurately gauged on the rolling machine. The wrapper is put on with a very ingenious machine. A piece of the leaf is laid by the operative on a perforated block about the size of a playing card.

By means of suction this piece of leaf is kept perfectly smooth. By a somewhat complicated system the wrapper is brought in contact with the filler, and a perfect all tobacco little cigar emerges. One of these machines will make 1 0,000 little cigars a day. By this system all contact with a human hand is avoided. An automatic system does the whole thing.

In the preparation work in this department a very ingenious machine is used, which takes the stem of the leaf out with great rapidity and with perfect accuracy. On another machine the leaf tobacco is cut and shredded and thus prepared for its office as a filler for the cigars. The finished material is placed in tin boxes and has to be carefully sorted as to color. The girls become very expert in putting ten little cigars of exactly the same shade in each box. They are aided in this work by excellent light, which is supplied partly by the numerous windows and partly by skylights which flood the big room with all the light which is required.

This room, besides being light and bright, is also scrupulously clean. New paint is put on every season. It is never allowed to get dingy..

Get access to Newspapers.com

- The largest online newspaper archive

- 300+ newspapers from the 1700's - 2000's

- Millions of additional pages added every month

About The Brooklyn Daily Eagle Archive

- Pages Available:

- 1,426,564

- Years Available:

- 1841-1963